The world of 3D printing is evolving at lightning speed, and a well-known manufacturer has just struck a major blow with its new Anycubic Kobra S1 Combo. This printer represents a major step forward for all 3D creation enthusiasts looking to combine quality, versatility and ease of use. I was lucky enough to be able to test this little marvel, and I have to say I was blown away right from the start!

The Kobra S1 Combo isn't just a 3D printer, it's a full-featured creation station. With its closed Core XY system and ACE Pro module for multi-color printing, it's aimed at beginners and experienced users alike. What particularly sets it apart from its competitors is its ability to dry filament during printing – a feature not found on Bambulab, Creality or even Prusa.

If you're looking for a versatile 3D printer that will enable you to produce multi-colored creations without breaking the bank, you've come to the right place. The Kobra S1 Combo could well be the machine you've been waiting for. But let's get to the heart of the matter…

Unpacking the Anycubic Kobra S1 Combo

When you receive the Kobra S1 Combo, the first thing you notice is the size of the box. Don't worry, it's normal: the printer is delivered almost fully assembled, which explains the generous dimensions of the packaging.

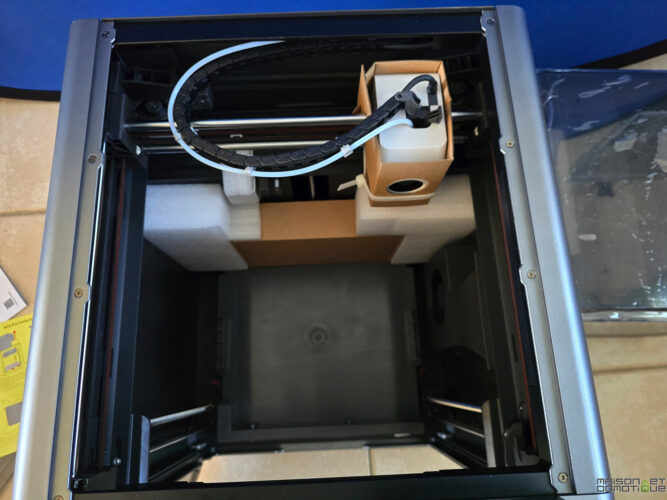

On opening the box, you discover a machine carefully protected by foam pads and plastic corners.

First visual contact is rather flattering. The printer boasts an elegant, mainly gray design, with a closed structure that inspires confidence. The machine's dimensions are 40 cm wide, 40 cm deep, and around 71 cm high with the ACE Pro module installed (which can reach 93 cm when the ACE cover is open). In other words, you'll need a dedicated space in your workshop or office!

The box contains :

- Pre-assembled Kobra S1 printer

- ACE Pro module for multicolor printing

- Double-sided textured PEI printing plate

- Power cables (one for the printer, one for the ACE Pro)

- Hub to connect ACE Pro module to printer

- PTFE tubes for filament feed-through

- USB key containing software and test files

- Activated carbon filter for air filtration

- Maintenance tools (Allen keys, nozzle unclogging needle, etc.)

- External spool holder (for filaments not compatible with the ACE Pro)

- A small creative kit (a Bluetooth speaker to assemble)

I particularly appreciated the presence of this small creative kit, which allows you to familiarize yourself with the machine while creating something useful. It's an attention to detail that shows Anycubic is thinking about the user experience as a whole.

The main technical specifications are impressive:

- 250 x 250 x 250 mm print volume

- Printing in up to 4 basic colors (expandable to 8 with a second ACE Pro)

- Print speed up to 600 mm/s (recommended 300 mm/s)

- Maximum acceleration 20,000 mm/s² (recommended 10,000 mm/s²)

- Noise level of 44 dB in silent mode

- Maximum nozzle temperature: 320°C

- Maximum platen temperature: 120°C

- Highly responsive 4.3″ touch screen

- Integrated camera for monitoring (480p resolution)

- AI print defect detection

One thing to note: the door and covers are made of plastic, not metal as on some high-end models. The price difference must be clearly explained, as this Kobra S1 Combo is barely half the price of a Bambu X1C…

The quality of the plastic is decent without being exceptional, but the whole remains solid. The magnetic closures work well and provide good thermal and sound insulation, which is the most important thing.

Installation: ready to use in record time

Installation of the Anycubic Kobra S1 Combo is surprisingly simple for such a complete machine. Unlike many 3D printers that require tedious assembly, this one arrives almost fully assembled. It takes just a few steps to get it up and running.

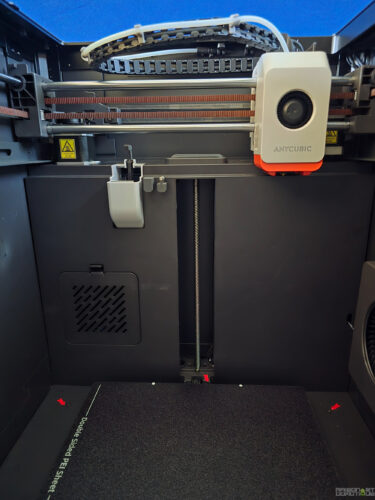

First thing to do: remove the various transport protections. In particular, there's a plastic block underneath the platen that needs to be unscrewed and removed, as well as the clips that hold the print head in place.

Everything is clearly indicated in the manual, with illustrations that make it easy to understand. It took me about 10 minutes to complete this step, taking my time and taking a few photos for this article.

Next comes installation of the ACE Pro module. First, the hub is installed on the back of the printer using the two screws provided.

Then connect the four PTFE tubes between the ACE Pro and the hub. There's no particular order. Just make sure you push the tubes in firmly and secure them with the safety clips to prevent them from dislodging during use.

Next, connect the two connecting cables: one 4-pin and one 6-pin.

Finally, install the activated charcoal filter in its housing at the rear of the printer. You can't go wrong!

If you intend to use filament spools directly on the printer (without using the ACE Pro), you'll need to install the spool holder on the rear of the printer. This is particularly useful for TPU, which can be difficult to feed through the ACE Pro system.

Once everything's plugged in, you switch on the printer and follow the on-screen instructions. The interface is intuitive and offers several languages, including French. The translation isn't always perfect (the term “titulaire” for the external coil holder made me smile), but it's still largely understandable.

The printer then performs a series of automatic calibrations: platen levelling, resonance compensation, nozzle testing… All this is done without any intervention on your part, simply by inserting the supplied USB key and starting the process. Allow around 15 minutes for this step.

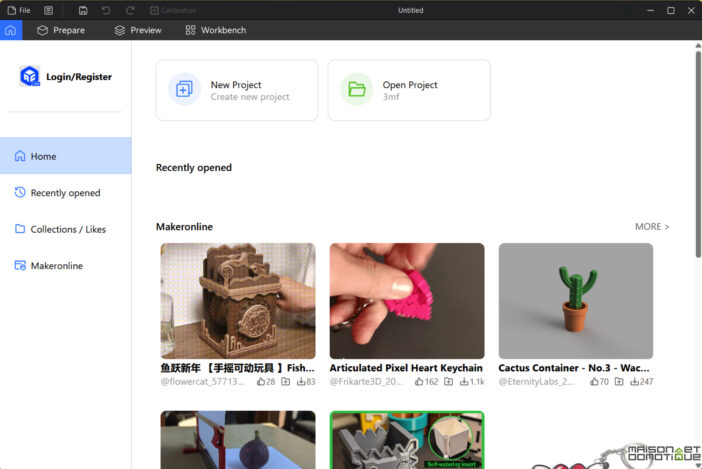

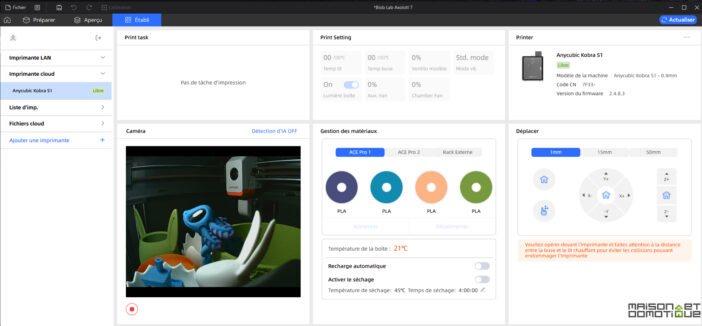

To complete the installation, you need to install the Anycubic Slicer software on your computer. This is a modified version of Orca Slicer, optimized for Anycubic printers. The software is available for Windows, but the Mac version is still in beta at the time of writing. If you're on a Mac, be prepared for some limitations for the time being.

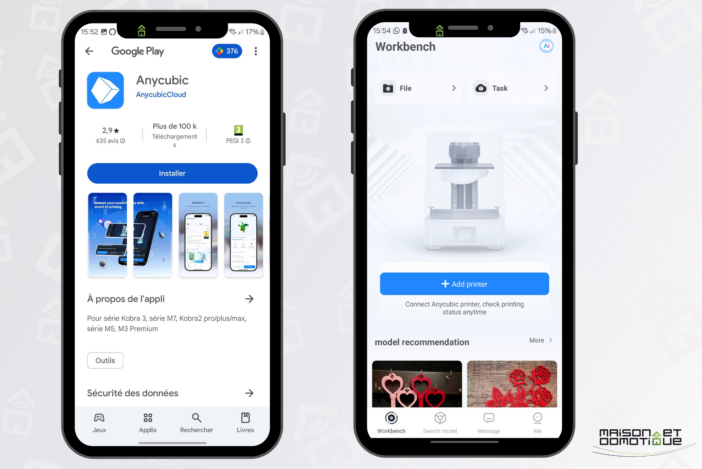

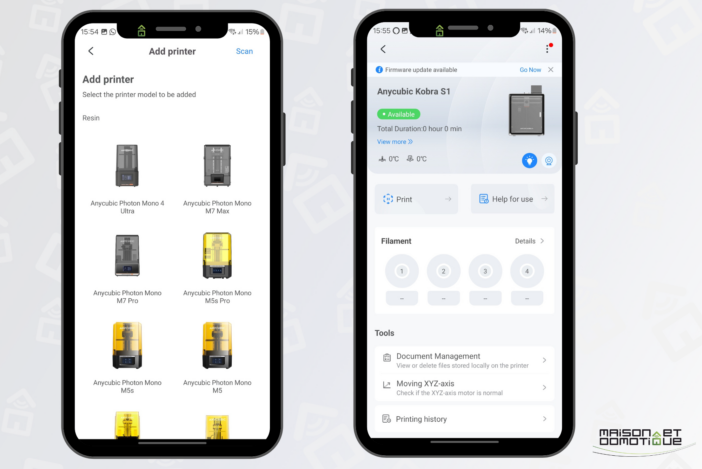

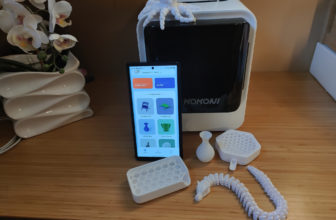

You can also install the mobile application, enabling you to control the printer remotely if required:

To keep an eye on work in progress (notably via the camera), or simply launch a print from the Anycubic collection, the mobile app proves quite sufficient.

Operation: a fluid, intuitive experience

Once installed, Anycubic Kobra S1 Combo is a pleasure to use. The touchscreen is highly responsive and the interface well thought-out, making it easy to get to grips with.

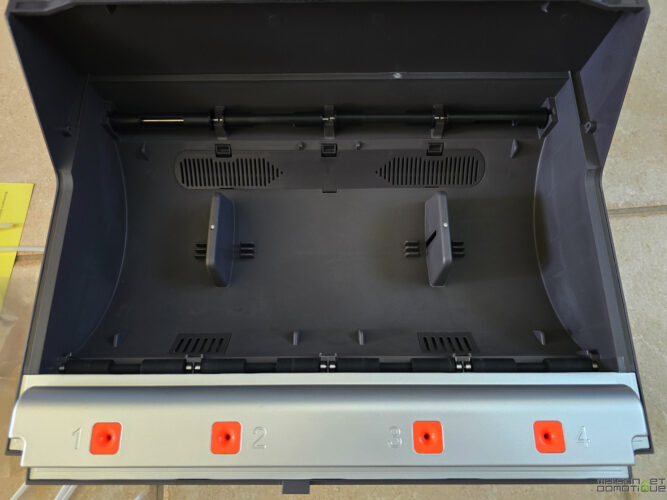

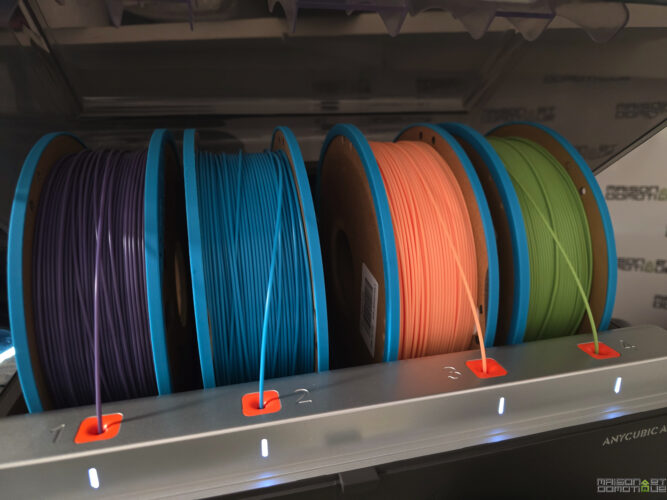

To load filament into the ACE Pro, simply open the cover, insert the spool, then push the filament into the inlet tube until it is detected. If you're using Anycubic spools fitted with RFID chips, the system will automatically recognize the filament type and color, as it does with the Bambu X1C, for example. Very practical! For other spools, on the other hand, you'll need to specify this information manually via the interface, which is also very easy to do.

A feature that makes all the difference: filament drying. The ACE Pro incorporates a dehydration system that allows the filament to be dried before or during printing. You can set the temperature (up to 55°C) and duration of drying. Three options are available: dry during printing, dry after printing, or start printing once the filament has dried. This is extremely useful for hygroscopic filaments such as PETG or ABS, which absorb moisture and can cause printing problems if too wet.

To start printing, you have several options:

- Directly from the screen, choosing from preloaded templates

- Via a USB key containing your gcode files

- Remotely, via Wi-Fi network and mobile application

- From Anycubic Slicer software on your computer

The Anycubic Slicer software is comprehensive enough to easily manage multicolor printing. The interface is similar to that of Orca Slicer, so if you're already familiar with the latter, you won't feel out of place. You can also access the Maker Online platform, which offers numerous 3D models optimized for Anycubic printers, including some specifically designed for multicolor printing. It's a bit like the Bambu community, which we like.

While printing, you can monitor the process via the built-in camera (even if its 480p resolution is rather limited) and adjust certain parameters such as temperature or fan speed. The machine is relatively quiet, especially in silent mode where it reaches around 54 dB with the door closed. In normal mode, count on 61 dB with the door open.

One point to note about the ACE Pro: when not in use, the internal fan continues to run, which can be a little annoying if the printer is installed in a living area. Fortunately, a firmware update has solved this problem, enabling the fan to stop when the device is on standby. Don't forget to update your printer!

Feedback: impressive results

After several days of intensive use, I can confirm that the Kobra S1 Combo delivers what it promises in terms of print quality. The results really live up to expectations, especially for a machine in this price range.

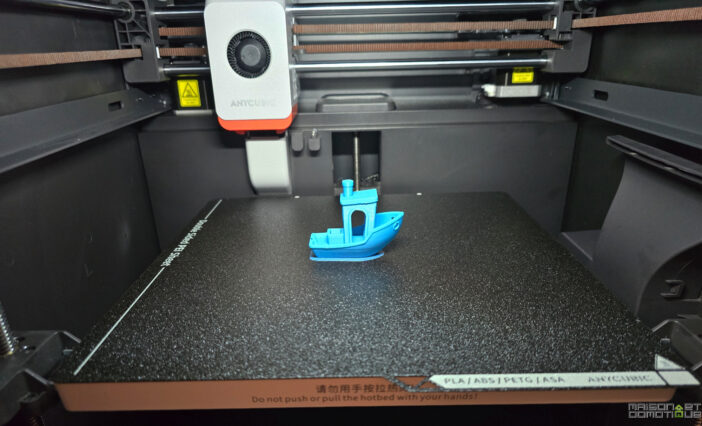

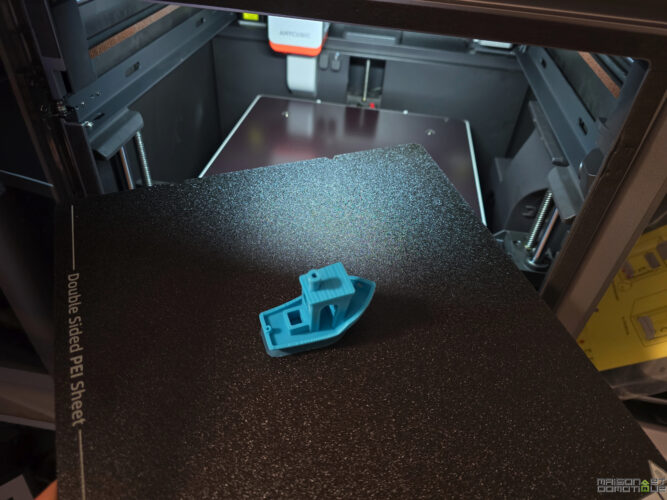

I started by printing the test models supplied with the printer, including the famous Benchy (the little boat that serves as a reference in the 3D printing world). The first was printed in 44 minutes with a very fine layer height, while a second was produced in just 15 minutes with a more standard layer height. In both cases, the quality was excellent, with well-defined details and perfectly aligned layers.

In PLA, prints are virtually perfect from the first attempt, using the slicer's default settings. The first layers adhere perfectly to the textured PEI plate, with no need to add anything, and details are well reproduced. In particular, I printed a small articulated lizard in 45 minutes, and the result was impeccable, with functional joints right out of the printer, with no post-processing required.

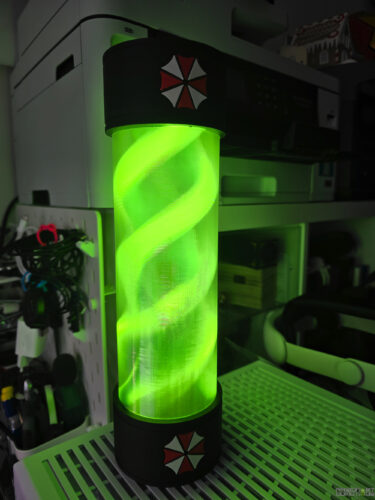

For PETG, a few adjustments are necessary. The default profiles suggest a temperature of 230°C, but I had to increase this to 250°C to avoid clogging the nozzle. Once this parameter has been adjusted, PETG prints are also of excellent quality. I made a tube with translucent PETG and another fluorescent filament that has perfectly smooth, even walls. Fans will recognize the reference ;-)

Printing in TPU (flexible filament) requires more adjustments. I had to go back to the drawing board several times to get a satisfactory result, considerably reducing the printing speed and increasing the temperature. The final result is correct, but this is clearly the machine's weak point. After all, I have to admit that I'm not yet very familiar with this type of filament, but I'm working on it!

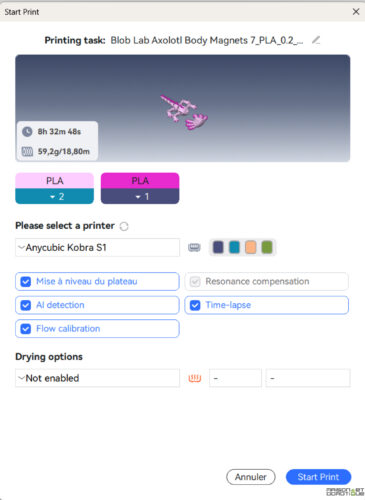

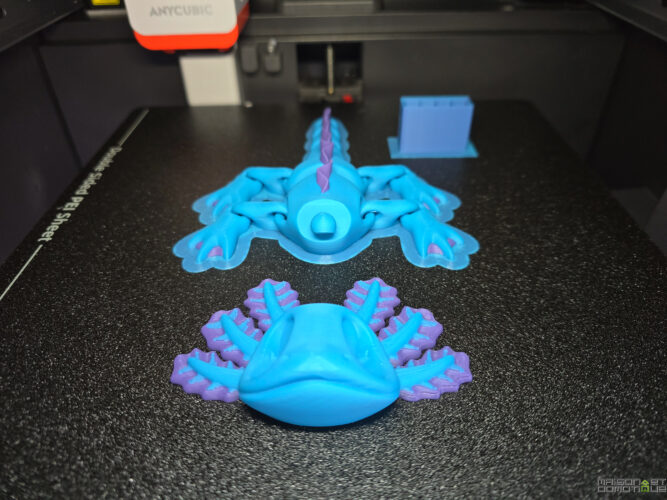

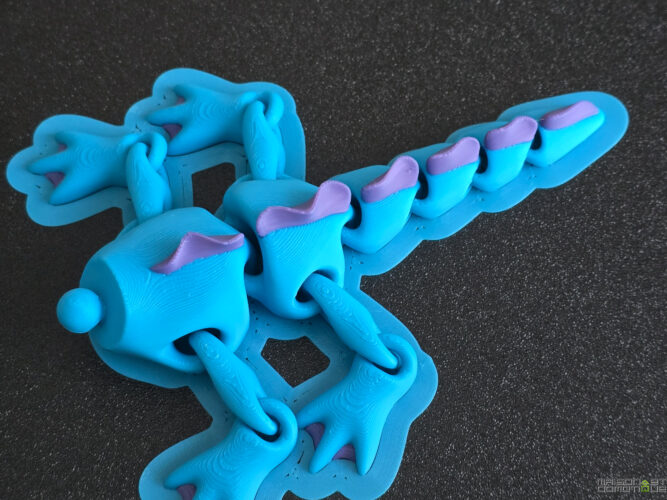

Where the Anycubic Kobra S1 Combo really shines is in multicolor printing. I tested a multicolor Axolo that took 8 hours to print, with spectacular results.

Transitions between colors are clean, with no smearing or unwanted blending.

For multicolor printing, the system works well but generates a lot of waste (the famous “poops” or purges). For example, to print a 10g part in multicolor, you could use up to 130g of filament in total, the rest being evacuated as waste. Unfortunately, this is the case for all multicolor systems of this type, not just Anycubic's.

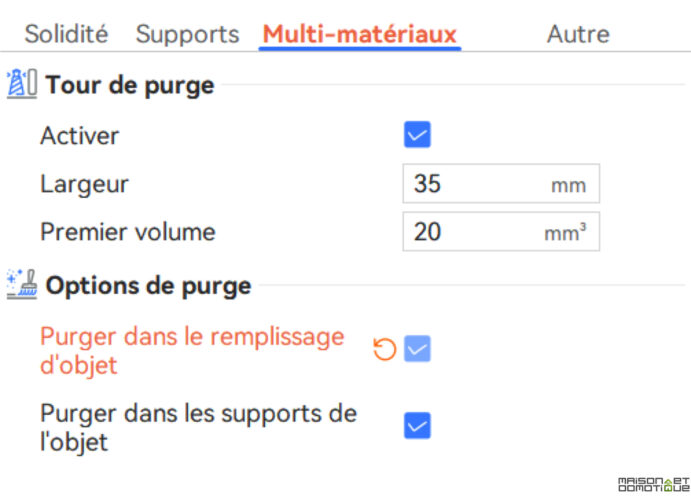

A little tip: the software allows you to ask for purging in the filling and supports, so as to waste as little material as possible (and provided that the walls of your object are not transparent, otherwise filling with another color might not be very aesthetic).

The filament drying function proved particularly useful for PETG and ABS. I intentionally left a spool of PETG in the open air for a few days to absorb moisture (not very difficult at the moment…), then used it with the drying function activated. The difference is obvious: no more bubbles, fewer “cracking” filaments during extrusion.

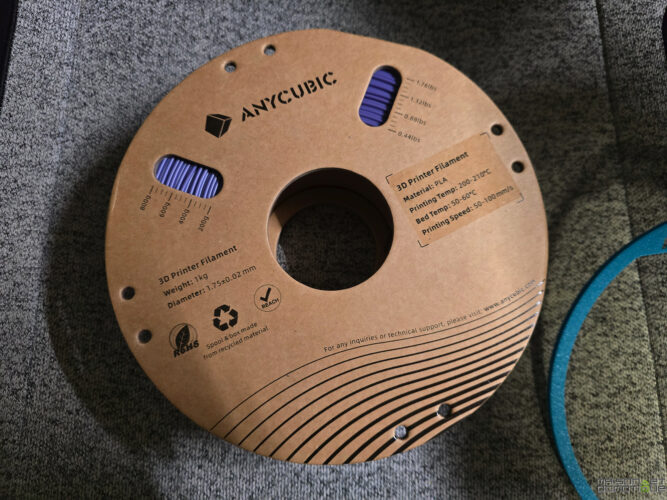

One last point: the Ace Pro can sometimes have trouble with cardboard spools, which warp and slide badly. For example, this coil is clearly flattened at the top.

In this case, it's best to print PLA frames to hold the spools in place. It's a minor detail, but in use it makes things much easier!

Conclusion: the Anycubic Kobra S1 Combo, an affordable revolution

After several weeks of intensive use, I can say without hesitation that the Anycubic Kobra S1 Combo represents a major breakthrough in the world of consumer 3D printing. This printer succeeds in combining performance, versatility and ease of use in a complete package at a reasonable price.

Its main asset? The ACE Pro system, which not only enables multi-color printing, but also dries the filament during printing. This unique feature (absent from Bambulab, Creality and Prusa) is a real game-changer for anyone working with hygroscopic materials such as PETG or ABS.

Print quality is simply stunning, especially with PLA where results are impeccable from the very first attempt. Details are sharp, layers perfectly aligned, and parts functional right out of the printer. Even if PETG and TPU require a few adjustments, results remain highly satisfactory once the right parameters have been found.

On the interface side, the responsive touchscreen and Anycubic Slicer software (derived from Orca Slicer) offer a fluid, intuitive user experience. The Wi-Fi connection and integrated camera enable effective remote monitoring, even if the latter's resolution remains limited.

Of course, not everything is perfect. The multicolor system generates a lot of waste (as do all systems of this type), and a few minor software bugs persist. The French translation of the interface sometimes leaves something to be desired, with terms like “titulaire” to designate the external coil support. But these negative points are largely offset by the machine's many advantages, and can easily be corrected via an update.

For around €599 (current price), you get an enclosed Core XY 3D printer, capable of multicolor printing, with an integrated filament drying system and outstanding print quality. It's exceptional value for money, making this technology accessible to a wider audience. Admittedly, this technology already existed, as we saw with the Bambu X1C. But at over €1,400, the latter is reserved for a discerning audience. Whereas the Anycubic Kobra S1 Combo, at less than half the price of the Bambu, opens its arms to a wider audience.

In short, if you're looking for your first multicolor 3D printer, or if you'd like to upgrade to a higher-performance model without breaking the bank, the Anycubic Kobra S1 Combo is well worth a look. It represents an excellent compromise between entry-level models and high-end professional machines, while offering unique features that set it apart from the competition.

Ultimately, the Anycubic Kobra S1 Combo is not just a good 3D printer, it's a gateway to a new world of creative possibilities. And that's priceless!

Please remain courteous: a hello and a thank you cost nothing! We're here to exchange ideas in a constructive way. Trolls will be deleted.